To improve generative design in product prototyping for structural engineering, integrate topology optimization, physics-informed neural networks (PINNs), and AI-driven multi-objective optimization to enhance structural efficiency and manufacturability.

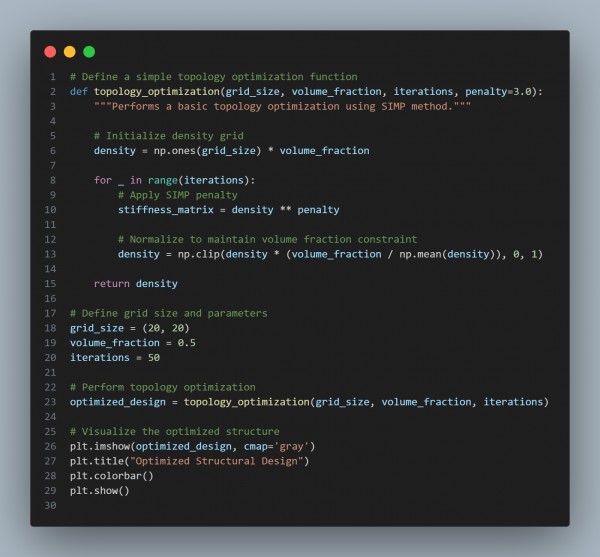

Here is the code snippet you can refer to:

In the above, we are using the following key points:

- Topology Optimization: Uses the Solid Isotropic Material with Penalization (SIMP) method for optimizing material distribution.

- Structural Efficiency: Iteratively adjusts the density field to improve structural performance.

- Volume Constraint Maintenance: Ensures the material remains within the allowable volume fraction.

- Visualization: Displays the optimized material layout to analyze load distribution.

- AI-Driven Refinement: Can be extended with neural networks for adaptive learning-based design generation.

Hence, by integrating AI-driven topology optimization and multi-objective structural analysis, we enhance generative design in product prototyping, ensuring optimal material distribution and improved manufacturability.

REGISTER FOR FREE WEBINAR

X

REGISTER FOR FREE WEBINAR

X

Thank you for registering

Join Edureka Meetup community for 100+ Free Webinars each month

JOIN MEETUP GROUP

Thank you for registering

Join Edureka Meetup community for 100+ Free Webinars each month

JOIN MEETUP GROUP