A company’s supply chain is the system it uses to get its products or services to market. It includes all the steps from acquiring raw materials to delivering the final product to the customer. Supply chain management (SCM) oversees and coordinates these activities to ensure they run smoothly and efficiently. This guide will let you know everything about SCM, from its basics to its importance in today’s business landscape.

What Is Supply Chain Management?

What is Supply chain management and Why is it important? Supply chain management (SCM) manages the flow of goods and services from suppliers to customers. It includes coordinating and managing all activities involved in the procurement, transportation, storage, and distribution of goods and services.

The main goal of SCM is to ensure that all goods and services are delivered to customers promptly and efficiently to achieve this, businesses need to have a well-organized supply chain that can effectively manage all human and material resources.

Human resources in the supply chain include managers, workers, and other professionals responsible for ensuring that goods and services are procured, transported, stored and distributed efficiently. Resources include raw materials, components, finished products, packaging materials, etc.

An effective SCM system can help businesses save their time, money and resources by reducing inventory levels, increasing the accuracy of orders, improving customer service levels and reducing lead times.

Also Read: Objectives Of Supply Chain Management Explained

Is Supply Chain Management Important? Briefly Explain All The Reasons.

SCM is the process of planning, performing, and managing the supply chain’s operations to provide improved customer service while reducing inventory and production costs.

A company’s supply chain includes all the steps in taking a product from its raw materials state to delivery to the end customer. Managing these steps effectively is critical to a company’s bottom line. Ineffective supply chain management can lead to delays in production, higher inventory costs, and lower customer satisfaction.

An essential part of supply chain management is ensuring that each step in the process is efficient and effective. It includes everything from sourcing raw materials to manufacturing products to delivering them to customers. For SCM to be successful, all supply chain members must work together efficiently and effectively.

There are many reasons why SCM is important. Perhaps most importantly, SCM can help improve customer satisfaction by ensuring that products are delivered on time and as promised. Additionally, SCM can help reduce inventory costs by providing that materials are only ordered when needed and that products are only produced when there is demand. Finally, SCM can help improve production efficiency by ensuring that all supply chain members work together efficiently.

In short, SCM is important because it can help improve customer satisfaction, reduce inventory costs, and improve production efficiency. These are just a few reasons SCM is so important for businesses today.

Related Course: Enroll for the AI in Supply Chain Management Course here!

Parts of Supply Chain Management

Planning

There are different aspects to consider when planning your supply chain management strategy. Here are some of the essential parts of SCM to keep in mind:

Inventory management: Managing your inventory is a crucial part of SCM. You need to be able to track your inventory levels and know when to order more supplies.

Order management: Keeping track of customer orders and ensuring they are filled correctly is another important aspect of SCM.

Transportation management: Planning how goods will be transported from supplier to customer is another essential part of SCM. You need to ensure that goods arrive on time and in good condition.

Warehousing: Proper warehousing is essential for keeping inventory levels organized and accessible.

Sourcing

In any SCM system, there are four main parts to the sourcing process:

- Planning and forecasting: This is predicting future demands for goods and services and planning accordingly. It includes everything from market analysis and trend forecasting to capacity planning and inventory management.

- Order management: Once demand has been forecasted, orders need to be placed with suppliers to meet this demand. It includes procuring the necessary materials and components and managing the production schedule.

- Transportation management: Goods must be transported from suppliers to manufacturers (and sometimes from manufacturers to customers). It needs to be done in a way that is both efficient and cost-effective.

- Inventory management: To ensure enough stock to meet customer demand, businesses must carefully manage their inventory levels. It includes setting appropriate safety stock levels, monitoring stock levels, and reordering stock when necessary.

Manufacturing

The manufacturing process is the most imperative part of the supply chain. For a company to succeed, all parts of the supply chain must work together efficiently and effectively. If products are not manufactured correctly, they will not meet customer expectations, and the company will lose money.

The manufacturing process has four main parts: planning, production, quality control, and packaging.

Planning is the first step in the manufacturing process. Companies must determine what products they will manufacture, how many they will need to produce, and when they will be required. Production is the second step in the manufacturing process. This is where companies make the products. They must have efficient production lines and enough workers to meet demand.

Quality control is the third step in the manufacturing process. Companies must test their products to ensure they meet customer specifications and are free of defects. Packaging is the fourth and final step in the manufacturing process. Products must be packaged correctly to arrive safely at their destination and are ready to be sold to customers. By enrolling in our AI Supply Chain Management course, you will learn about advanced quality control techniques. Packaging is the fourth and final step in the manufacturing process. Products must be packaged correctly to arrive safely at their destination and be ready to be sold to customers.

Delivering

In Supply Chain Management, the term “delivering” refers to getting goods and materials from suppliers to customers. This includes everything from procuring raw materials, manufacturing products, warehousing and distributing finished goods, and managing returns and customer service.

An adequate supply chain delivers value to customers by proving the right product at the right price. To do this, businesses need to have a clear understanding of their customer’s needs and expectations. They must also have a good working relationship with their suppliers to ensure that goods and materials are delivered on time and meet quality standards. Furthermore, they need efficient systems and processes to manage inventory levels, warehousing, distribution, and customer service.

Returning

When it comes to SCM, there are a few different areas you need to be aware of. In this section, we will discuss the different parts of SCM and how they are pivotal in the process.

The first part of SCM is the procurement process. This is where companies purchase the raw materials or products they need to create their final product. The procurement process can be very complex, as there are many different suppliers to choose from, and each one offers different terms and conditions.

The next part of SCM is the manufacturing process. This is where the raw materials or products are transformed into the final product. The manufacturing process can be very complex, as many different steps are involved in creating a final product.

The last part of SCM is the distribution process. This is where the final product is delivered to the customer. The distribution process can be very complex, as many different channels can be used to distribute a product.

Supply Chain Management Models

Continuous Flow Model

The continuous flow model is a type of SCM that emphasizes the uninterrupted flow of goods and materials from suppliers to customers. This model is also known as the “just-in-time” or “JIT” model.

In a continuous flow model, suppliers provide materials to the manufacturing process as they are needed. There is no finished goods inventory; products are completed and shipped to customers as soon as they are finished.

This type of supply chain management requires close coordination between suppliers and customers and between different parts of the manufacturing process. Because there is no buffer of inventory, any disruptions in the flow can cause significant problems.

The continuous flow model is most commonly used in manufacturing industries where products are produced in large quantities and must be shipped out quickly. This type of supply chain management can also be used in other industries, such as food service or healthcare, where freshness or timeliness is essential.

Also Read: What Is The Scope Of Operations Management?

Agile Models

There are many agile models, but the most popular ones are Scrum and Kanban.

Scrum is a very popular agile model that is often used in software development. It is based on short cycles, called sprints, which are typically two weeks long. During a sprint, all team members work together to get the work done. At the end of each sprint, the team reflects on what went well and what could be improved for the next sprint. The product owner then reviews it.

Kanban is another popular agile model used in software development or project management. It is based on visualizing work as it moves through a system. Work is represented by cards that are moved from one stage to the next as it gets completed. This allows team members to check what must be done and where things are in the process.

Both Scrum and Kanban are great choices for agile supply chain management models. They both offer transparency and flexibility, which are two key elements of successful agile supply chains.

Fast Model

In the business world, the term “supply chain management” (SCM) describes the process of managing materials, information, and finances when they walk in a linear direction from suppliers to manufacturers to retailers to consumers.

SCM aims to create a system that efficiently and effectively moves goods and services from point A to point B while minimizing waste, maximizing resources, and reducing costs. To achieve this goal, businesses need to have visibility into every stage of the supply chain to identify obstructions and make necessary adjustments.

Businesses can use many different models to improve their supply chain management. The most popular model is the Fast Model, which Dr Michael Orr developed.

The Fast Model is based on the premise that businesses need to be able to adapt rapidly to changes in the marketplace. To do this, companies must have a clear understanding of their customer’s needs and be able to respond quickly to changes in demand. The Fast Model also emphasizes the importance of collaboration among all supply chain members. By working together, businesses can more effectively identify problems and find solutions.

The Fast Model is an effective way for businesses to improve their supply chain management. To enhance your SCM processes, consider using the Fast Model as a guide.

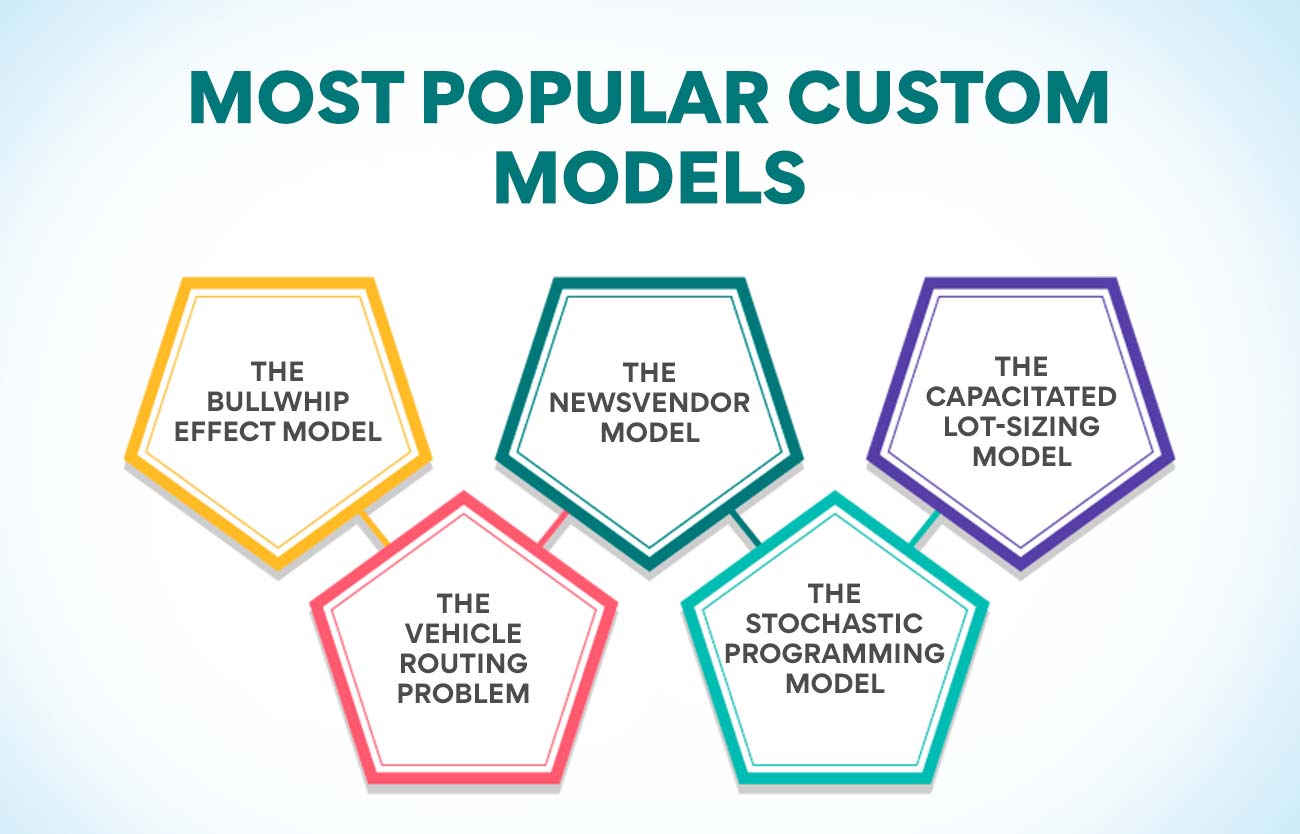

Custom Model

The supply chain management landscape is constantly evolving, and new models are emerging all the time. Custom models are designed to cater to the specific needs of a business or industry and can be adapted to changing conditions.

Some of the most popular custom models include:

- The bullwhip effect model: This model predicts how changes in demand will ripple through the supply chain. It can help companies avoid stockouts and overages and manage inventory more effectively.

- The newsvendor model: This model is used to optimize stocking levels for perishable goods. It takes into account factors like lead time, demand variability, and cost of inventory.

- The capacitated lot-sizing model: This model helps companies determine the optimal production quantity for each order, taking into account capacity constraints and costs.

- The vehicle routing problem: This model finds the best route for delivery vehicles, taking into account factors like traffic, distance, and time windows.

- The stochastic programming model: This model optimizes decision-making under uncertainty, using probabilities to identify the most likely outcomes of different actions.

Custom models can be complex, but they offer tremendous benefits to companies using them. By better understanding their supply chains, they can make more informed decisions that lead to improved efficiency and profitability.

Conclusion

Supply chain management is a vast and complex topic, but we hope this article has given you an excellent introduction to the basics. Whether you’re looking to streamline your own business’s supply chain or you’re just curious about how it all works, our course on supply chain management will cater to all your requirements. Check out Advanced Certificate in Operations, Supply Chain and Project Management and get to know supply chain management up close.

More Information:

What is Supply Chain Optimisation? An overview

What Is A Supply Chain Control Tower? Types & Uses

Green Supply Chain Management: What It Is and Why It Matters?