Have you thought about how goods and services by brands are delivered most effectively and practically? What goes behind the scenes that make the entire journey from production and supply to management seem perfect? Successful operations management in place is the secret sauce to the triumph of millions of organisations.

Operations management is an indispensable function that sets the foundation of any organisation. Without effective operations management, an organisation would be unable to produce goods and services efficiently or meet the needs of its customers. While it may seem like a complex and daunting topic, it doesn’t have to be.

Operations management is a critical aspect of any business. It’s not just about overseeing the production and delivery of products or services; it’s also about ensuring that operations are running efficiently and effectively to maximise profits. From understanding how to optimise process flows, and developing strategies for managing inventory and personnel, to understanding the nuances of cost analysis — operations management covers various topics.

In this blog post, we will provide a beginner’s guide to operations management (OM) and discuss some of the most important topics that you need to know. By understanding its basics, you can make more informed decisions about the business and its operations.

Why does Business Operations Management Hold Immense Significance?

“A recent study by the Harvard Business Review found that companies with superior operations management are twice as likely to ace the top quadrant of financial performance in the industry.”

In today’s competitive business environment, organisations need to have robust operations management processes in place. The goal of operations management is to optimise the use of resources that adequately cater to diverse customer requirements.

Operations management is concerned with all aspects of the production process, from sourcing raw materials to delivering finished products. It includes the management of facilities, equipment, and staff. OM is also responsible for the planning and execution of production tasks. Here are the core processes of OM:

Effective Production: It ensures that resources are used efficiently to produce goods and services. This includes reducing wastage and maximising the use of resources for product success.

Adequate Planning and Scheduling: It assures that production tasks are planned and scheduled to meet business goals, production capacity, and customer demand.

Quality Control: OM is responsible for every step of quality check, ensuring that production and supply complement the business objectives and that finished products meet customer expectations.

Managing Facilities, Equipment, and Staff: It ensures that facilities and equipment are adequately maintained and that staff are appropriately trained and motivated towards the common goal.

Monitoring and Controlling the Production Process: This includes monitoring production metrics and making changes to the production process as needed.

Continuously Improving Efficiency: OM paves ways for improving the production process and making it more efficient.

Increasing Profitability: This is the ultimate goal of all businesses, and operations managers should always look for ways to increase profitability.

Also Read: What Is The Scope Of Operations Management?

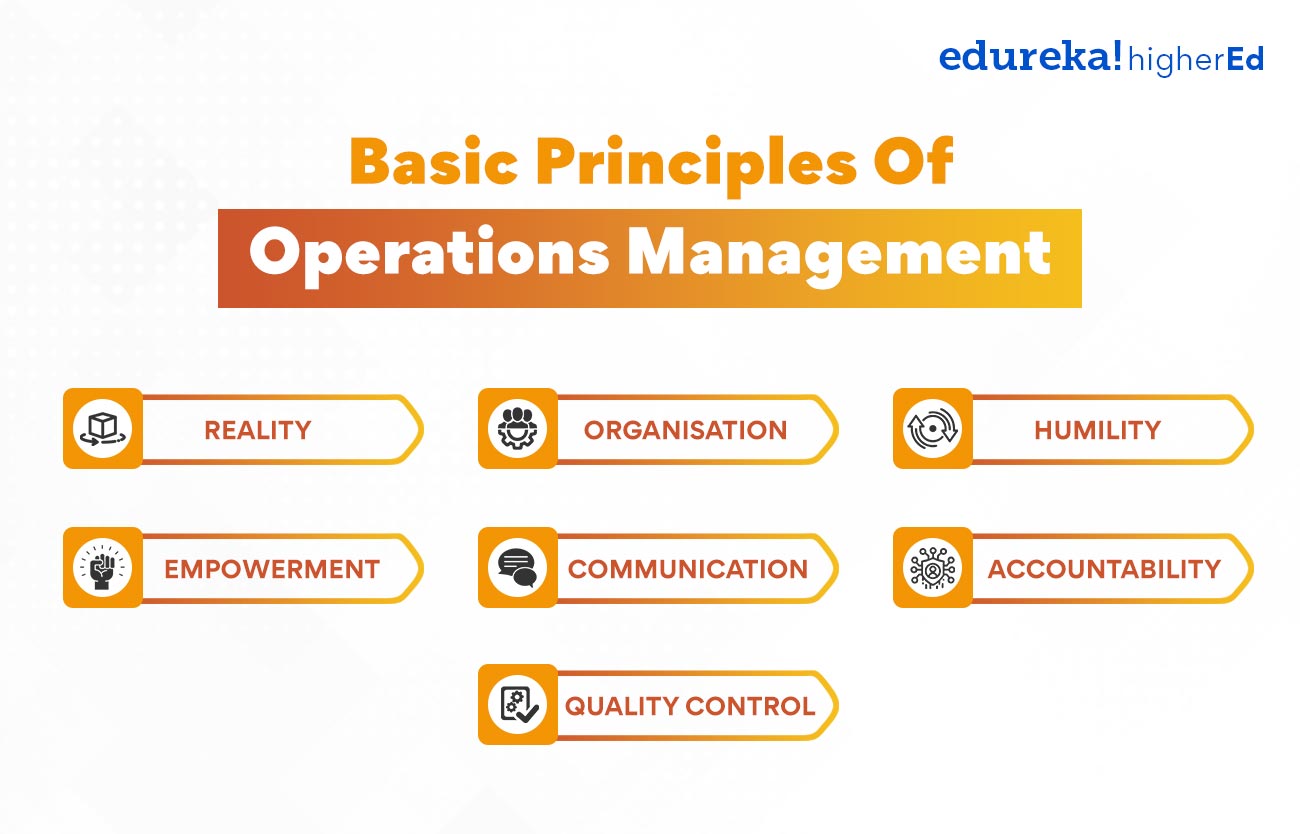

Basic Principles Of Operations Management

Operations management is a complex field with many different aspects to consider. However, by understanding the basic principles of the operations management process, you can start to make a difference in your organisation. Implement these principles in your organisation, and you will soon see the benefits. Principles of OM, according to Randall Schaeffer.

- Reality: There is no perfect way to run an organisation, and there will always be room for improvement. OM process should focus on the core problem and work out ways to improve it.

- Organisation: Every organisation is different, and so the way you manage your operations will be unique to your company. You must understand your organisation’s strengths and weaknesses to ensure optimal results.

- Humility: The trial and error method is only advisable when you have enough resources and time. Hence, it is always essential to understand the limitation will allow you to work on the optimum capacity that brings results.

- Empowerment: Empower your employees to make decisions and take action. The more empowered they are, the more engaged they will be in their work.

- Communication: Clear and honest communication is the essence of successful operations management. Make sure everyone is on the same page, and don’t be afraid to give feedback.

- Accountability: It is important to be accountable for the results you bring as an operations manager.

- Quality Control: Quality control is essential to ensure that your products or services meet your customers’ needs. Use proven systems and tactics to track and improve quality over time.

These are only a few principles of operations management. With the appropriate implementation of these principles, you can start to make a difference in your organisation. You can soon reap the seeds of improved efficiency and productivity.

Want to learn the nitty-gritty of operations management and step into the shoes of an operations manager? We have an amazing and interactive course, i.e., Advanced Certificate in Operations, Supply Chain, and Project Management. Give it a try!

What Are The Strategic Operation Management Decisions?

Each decision in operation management has different implications and considerations, but all are important to the success of your business. Hence, these should be made considering the company’s goals, resources, and constraints. Here are a few of the strategic decisions that operations managers must make.

Operations and Supply Chain Management

The strategic decisions in these two areas mainly focus on the efficiency and effectiveness of the company’s production process. It overlooks the entire production process, from acquiring raw materials to delivering finished products to customers. The objective is to minimise waste and maximise resources while meeting customer demand.

Human Resources Management

The decisions are focused on attracting, developing, and retaining employees. This includes creating and enforcing employee policies to providing training and development opportunities. It creates a workforce that is skilled, motivated, and committed to the company.

Inventory Management

This is a critical area for any company that manufactures or sells products. The ideal objective is to keep enough inventory on hand to meet growing customer demand while not keeping much capital in inventory. It might be a challenging balance to strike, and the strategic decisions in this area are focused on achieving it.

Forecasting and Capacity Planning

Another critical area for manufacturing and selling companies is forecasting and capacity planning. This includes making decisions about what products to make, how much of each product to make, and when to make it. The intention here is to minimise the risk of overproduction or underproduction while being relevant to the target audience.

Facility Management

The strategic decisions in this area are focused on the layout, design, and maintenance of the company’s facilities. This includes everything from choosing the facility’s location to designing the production process’s layout. It helps in creating a safe and efficient working environment for employees.

Operations Scheduling

The final area of operations management is scheduling. This includes making decisions about when to start and finish each task in the production process. The goal is to minimise downtime and maximise resources while still meeting customer demand.

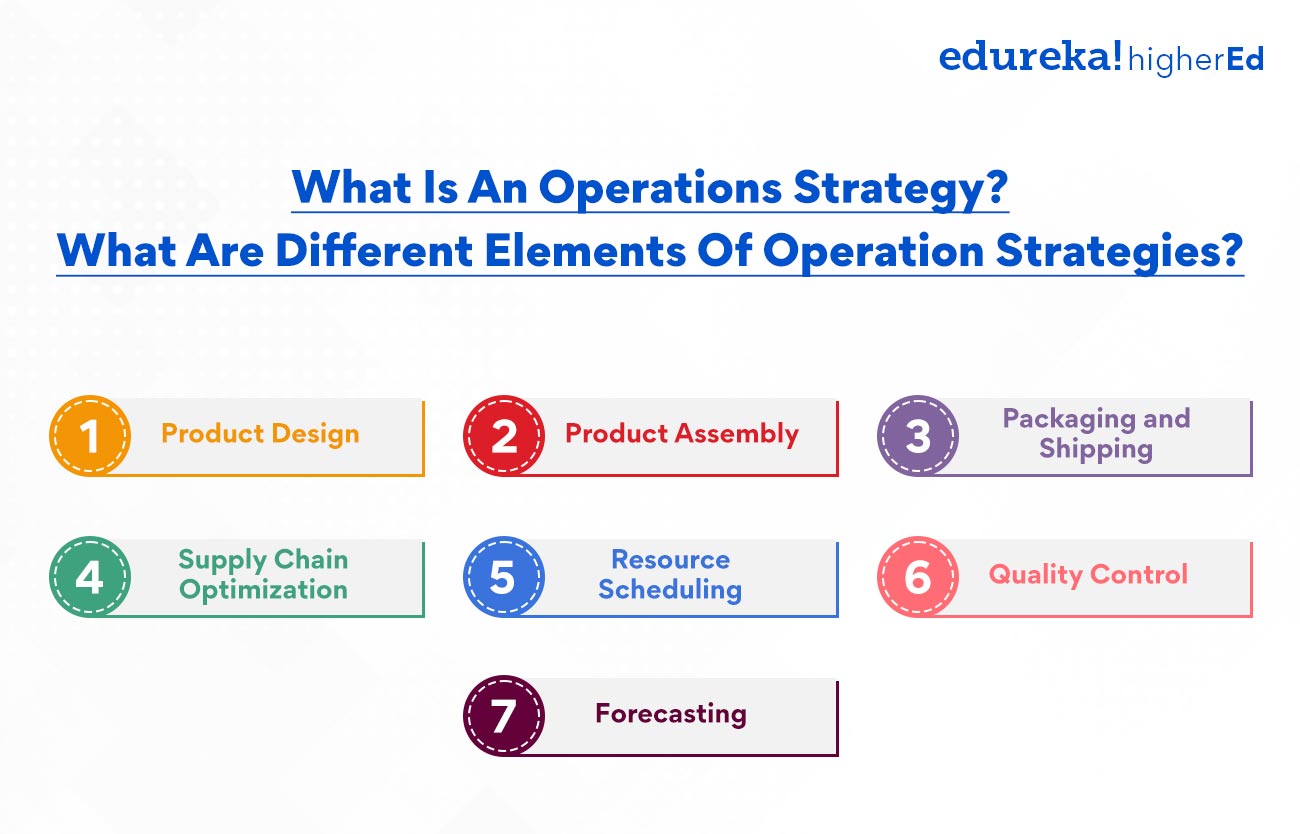

What Is An Operations Strategy? What Are Different Elements Of Operation Strategies?

An operations strategy is a plan for how an organisation will use its resources to create value for its customers. With an efficient operations strategy, the company can produce goods or services at a lower cost or generate more revenue than its competitors. The main aim of the operations strategy is to improve the company’s competitive position.

Crucial elements of operation strategy include:

Product Design: Product design involves creating products that meet customer needs and can be produced at a cost that allows the organisation to profit.

Product Assembly: Product assembly is the process of putting together the components of a product, making it profitable for the company and relevant for the customers.

Packaging and Shipping: Packaging and shipping are responsible for getting products to customers safely and promptly.

Supply Chain Optimization: Supply chain optimisation ensures that all components of the supply chain are working together efficiently to deliver products to customers.

Resource Scheduling: Resource scheduling is allocating resources, such as machines and workers, to tasks to meet production goals.

Quality Control: Quality control ensures that products meet customer quality standards and can be delivered on time.

Forecasting: It is a method of estimating future demand for products to ensure that the necessary resources are available.

Also Read: Decision Making in Operations Management: Key Points

Systems And Techniques To Improve Operation Management

Deploying the right mix of resources and processes is essential to achieving the desired outcome. There are a variety of different tools and techniques that can be used to achieve this goal.

One popular tool is known as Six Sigma. This methodology uses various statistical tools and techniques to identify and eliminate sources of waste and variation. Six Sigma has been proven to be an effective way to improve operations in multiple industries.

Another popular tool is lean manufacturing. This approach eliminates wasted time, effort, and resources by streamlining processes and eliminating unnecessary steps. Lean manufacturing has been an effective way to improve productivity and efficiency in various industries.

Both Six Sigma and lean manufacturing are popular systems that can be used to improve operations. There are a variety of other tools and techniques that can also be used. The best way to determine which approach is best for your organisation is to assess your specific needs and pick the best course of action.

Operations Management Changing The Dimensions Of The Business Industry?

The operations management field is evolving rapidly due to technological changes and the global economy. This has led to new challenges for businesses, which must now adapt their practices to stay competitive. As a result, the role of an operations manager is becoming increasingly important.

Operations managers are responsible for ensuring that all aspects of a company’s operations run smoothly and efficiently. This includes overseeing production, managing inventory, and coordinating the distribution of products and services. In addition, operations managers must be able to communicate effectively with other departments within the company to ensure that all goals are met.

The changing landscape of business has emphasised operations management more than ever. The rise of global markets and the need for faster turnaround times have made it essential for companies to have an efficient and effective operations management system in place. In addition, the increasing complexity of products and services has made it necessary for operations managers to adapt quickly to dynamic changes.

Why Operations Management Is A Booming Field Of Opportunities?

Operations management is a vital business activity of managing the resources which are responsible for the creation and delivery of the company’s products and services. It includes the management of the processes which transform the inputs into outputs. The resources managed by operations managers include human resources, machines, materials, information, and energy.

Operations management is a significant part of any business and plays a vital role in the company’s growth. It is responsible for ensuring that the company’s products and services are delivered promptly and efficiently. OM is a very challenging field, requiring a lot of skills and knowledge.

The operations manager must be able to plan, organise, control, and lead the activities of the operations team. He must also be able to make decisions in a fast-paced environment and must be able to handle the pressure of the job. Operations management is a growing field, and there are many opportunities for those who want to ace this ever-growing vertical.

“The operations management field has grown by 32 percent from 2010 to 2020, according to the U.S. Bureau of Labor Statistics.”

This growth is expected to continue as businesses increasingly rely on operations managers to help them address the challenges encountered in this ever-changing business landscape. If you’re interested in starting a career in operations management, now is the time to strike while the iron is hot.

By taking the time to understand how it works and its objectives, you’ll be better prepared to impact your company’s bottom line positively. We are offering a brilliant certificate course that will make you future-ready.

Take some time to check out our Advanced Certificate in Operations, Supply Chain, and Project Management. See what it has to offer in bringing your dreams to fruition.

Responsibilities Of Operations Manager

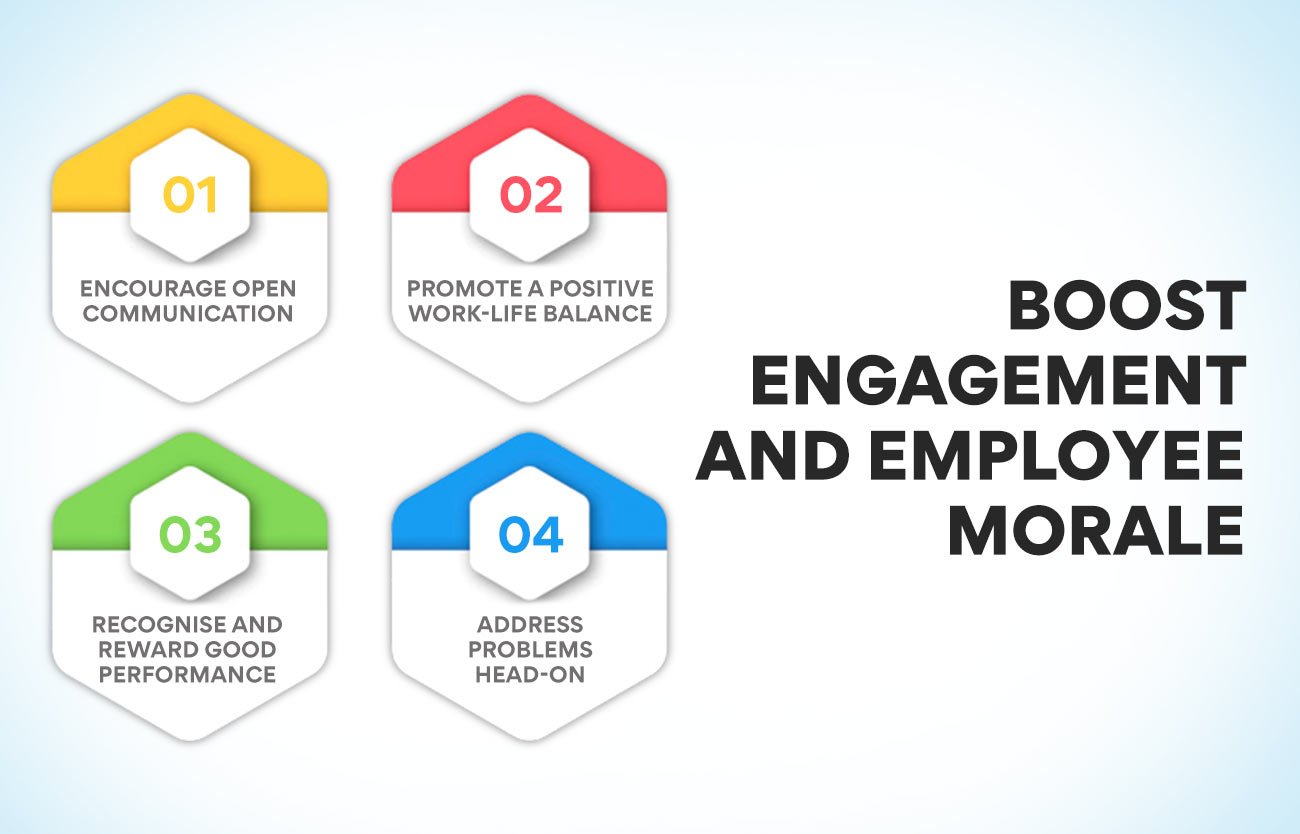

Boost Engagement And Employee Morale

As an operations manager, one of your key responsibilities is to boost engagement and employee morale within your team. You can do this in several ways, but it’s important to remember that each team is different, and what works great for one may not be similar for another.

- Encourage open communication: One way to boost engagement and morale is to encourage open communication between employees and management. This can be done through regular team meetings, 1-on-1s, or even just an open-door policy.

- Promote a positive work-life balance: Another way to boost engagement and morale is to promote a positive work-life balance for your employees. It means ensuring that they have adequate time off, flexible working hours, and access to resources (e.g., child care) that allow them to maintain a healthy lifestyle outside of work.

- Recognise and reward good performance: Another great way to engage and motivate employees is to recognise and reward good performance. It is mainly done through financial incentives, public recognition, or even verbal praise.

- Address problems head-on: Finally, addressing any problems head-on as they arise is important. If there are issues with job satisfaction, productivity, or turnover, addressing them early on will help prevent them from becoming major problems down the road.

Performance Analysis

The Operations Manager ensures that operations are running smoothly and efficiently. It includes performance analysis to identify areas of improvement.

Operations managers must be able to identify problems and areas of improvement within their team. They need to have robust analytical skills to evaluate data and make decisions based on their findings.

Performance analysis is an essential part of the operations manager’s job. They must constantly monitor operations and look for ways to improve efficiency and quality. By doing so, they can ensure that the company is running as smoothly and efficiently as possible.

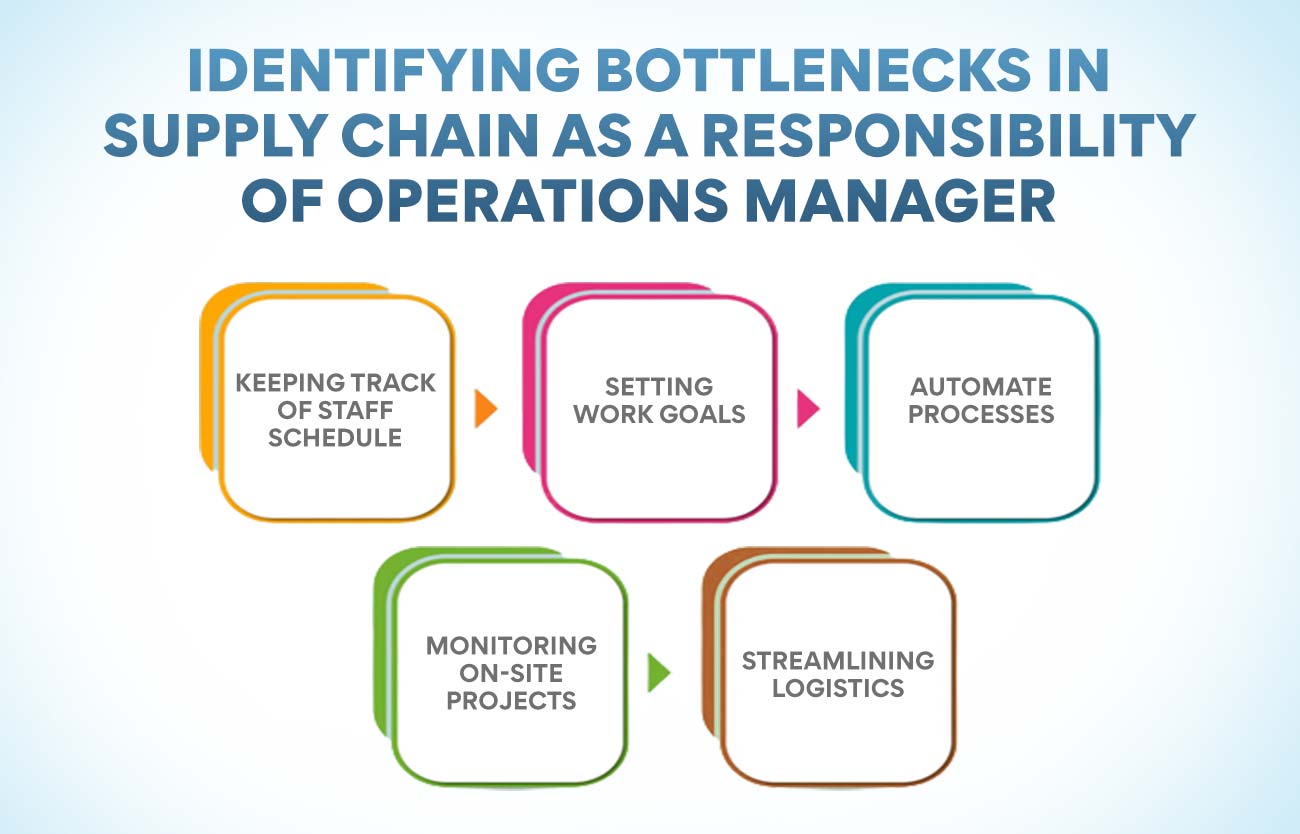

Identifying Bottlenecks in Supply Chain As A Responsibility Of Operations Manager

Operations managers are responsible for identifying bottlenecks in the supply chain and taking corrective action to mitigate them. The goal is to ensure that goods and services flow smoothly through the supply chain, from supplier to customer.

Bottlenecks can occur at any point in the supply chain, but they are most likely to happen at points of high demand or where there is a lack of capacity. Identifying bottlenecks is not always easy, but there are some tell-tale signs that something is amiss. These include:

- Unusual delays in shipments

- Inventory buildup at certain locations

- Customer complaints about late or missing deliveries

If you suspect a bottleneck in the supply chain, it’s essential to take action quickly. The longer the bottleneck persists, the greater the impact on operations and the company’s bottom line. There are a few options for addressing bottlenecks:

- Add additional capacity at the bottlenecked location

- Reorganise the supply chain to bypass the bottlenecked location

- Source an alternative supplier or product

Keeping Track of Staff Schedule

As the operations manager, one of your key responsibilities is keeping track of your staff schedule. Doing so ensures that you have adequate operation coverage and helps avoid costly scheduling errors.

There are plenty of methods to keep track of your staff schedule. One option is to use a paper-based system, such as a whiteboard or spreadsheet. It can be effective if you have a small team and everyone is aware of the schedule. However, it can become cumbersome as your team grows and people’s schedules change frequently.

Another option is to use an online scheduling tool, such as When I Work. This allows you to create and manage employee schedules from any internet-connected device easily. It also offers time clock integration and shift reminders, which can help ensure that your employees clock in and out correctly.

Whichever method you choose, it’s essential to keep communication open with your team so that everyone is aware of the schedule and knows when they are expected to work.

Setting Work Goals

Operations management ensures that an organisation’s operations are efficient and effective. One of the key ways in which operations managers do this is by setting work goals.

Work goals help ensure that everyone in the organisation is aware of what needs to be done and when. They also provide a way of measuring progress and determining whether or not an organisation is on track to meet its objectives.

Operations managers need to take into account several factors when setting work goals. These include the resources available, the time frame for goal achievement, and the organisation’s specific objectives.

Work goals must be realistic and achievable. If they are too ambitious, they may lead to frustration and discouragement among employees. On the other hand, if they are too easy, they may not provide enough challenge or motivation.

Operations managers should consult with other members of senior management when setting work goals. It will ensure that the goals are aligned with the organisation’s overall strategy. Once work goals have been set, it is important to communicate them to all staff members so that everyone is aware of what needs to be done.

Automate Processes

As an operations manager, it is your responsibility to automate processes to streamline your business’s operation. Automating processes has many benefits, including reducing costs, increasing efficiency, and improving quality control.

When deciding which processes to automate, it is essential to consider all the specific needs of your business. Automating a process that is not well suited to your business can actually lead to increased costs and decreased efficiency.

Once you have selected the appropriate processes for automation, you will need to implement the automation technology. It can be done using various methods, including software applications, robotic devices, or even simple scripts.

After the automation technology is in place, you will need to monitor the results closely to ensure that the desired benefits are achieved. Adjust the automation settings as needed to fine-tune the process and achieve optimal results.

Monitoring On-Site Projects

As a responsible Operations Manager, it is essential to monitor on-site projects to ensure they run smoothly and efficiently. This may include keeping track of project milestones, budget, and resource allocation. It is also important to communicate with project managers and other team members to get updates on the project’s status. By monitoring on-site projects, Operations Managers can identify any potential problems and take corrective action to avoid any disruptions in the project timeline.

Streamlining Logistics

As the operations manager, your responsibility is to ensure that logistics are streamlined within your company. This means ensuring that goods and materials are received and shipped promptly and efficiently.

There are a bunch of key things you can do to streamline your company’s logistics:

- Create a detailed shipping and receiving schedule. This schedule should include all deadlines for shipments and deliveries, as well as any special instructions (such as rush orders or fragile items).

- Have a system in place for tracking inventory. It will help you know what needs to be ordered and when, so you can avoid stock-outs or overages.

- Work with your suppliers to establish efficient shipping methods. It could include using drop-shipping or consolidating orders to reduce shipping costs.

- Stay organised! Keep accurate records of all shipments, deliveries, and inventory levels. This will help you troubleshoot any arising problems and keep your logistics running smoothly.

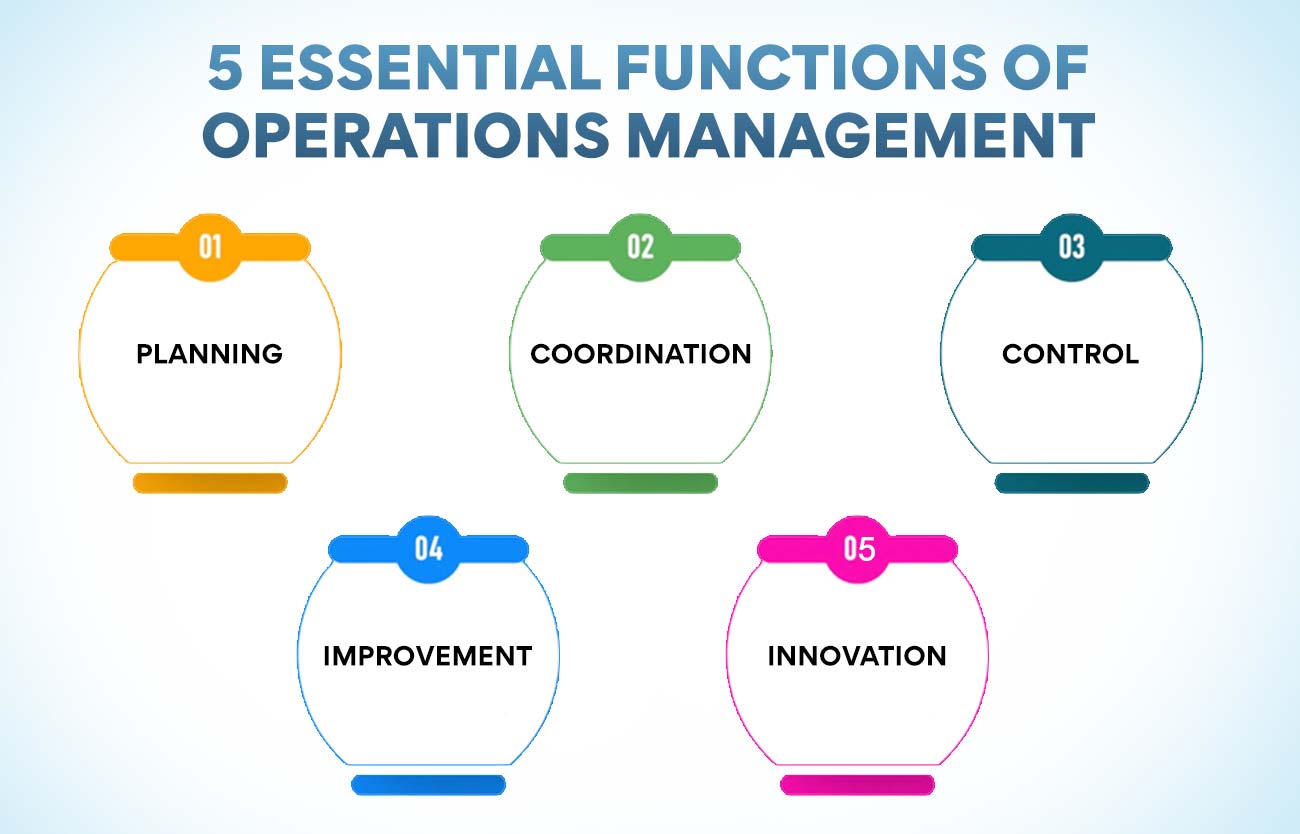

Important Functions of Operations Management

Operations management is a critical function for any organisation. It is responsible for planning, coordinating, and controlling the resources required to produce goods and services.

There are 5 essential functions of operations management:

- Planning: Operations managers must plan production schedules, labour requirements, and raw material needs. They also develop plans for new products and services, as well as modifications to existing ones.

- Coordination: Operations managers coordinate the activities of different departments and personnel to ensure that production goals are met.

- Control: Operations managers monitor production processes and identify problems or areas for improvement. They also develop quality control procedures to ensure that products meet customer expectations.

- Improvement: Operations managers constantly strive to improve production efficiency and quality. They may implement new technologies or processes or redesign workflows to eliminate bottlenecks and waste.

- Innovation: In addition to improving existing operations, operations managers must also be proactive in developing new products and services that will meet future customer needs.

Ethical Conduct

The ethical conduct of operations management is challenging because it requires applying principles of ethics to the specific circumstances that arise in the operations. These principles include respect for persons, beneficence, non-maleficence, justice, and fidelity.

The challenge for operations managers is to apply these principles to protect the rights and welfare of those affected by their decisions and actions. In some cases, this will require balancing competing interests or considering the impact of one’s actions on future generations.

Sustainability

As the world becomes aware of the need to operate sustainably, the challenge for operations management is finding ways to do so while still achieving desired performance levels. Achieving sustainability requires systems thinking approach that considers the environmental, social and economic impacts of business decisions.

To be sustainable, businesses must find ways to reduce their environmental impact. This can be doneachieved through various methods, such as using renewable energy sources, reducing waste and emissions, and increasing efficiency. Social sustainability is also important and includes considerations such as fair labour practices, supply chain management and community engagement.

Finally, economic sustainability ensures that businesses are able to continue operating in the long term by generating revenue and profits while still adhering to principles of social and environmental responsibility.

Communication

Operations management is the process of overseeing, planning, and controlling the operations of a business. It includes the management of resources, such as raw materials, equipment, and human resources.

Communication is one of the most important aspects of operations management. Without effective communication, it would be difficult to coordinate the various activities involved in running a business. Operations managers need to be able to communicate clearly with their employees and other stakeholders.

There are various challenges that can make communication difficult. For example, different people may have different levels of understanding or may use different jargon. There may also be cultural differences that make communication more difficult.

Operations managers need to be aware of these challenges and take steps to overcome them. They should ensure that they are clear and concise when communicating with employees and other stakeholders. They should also try to use plain language instead of jargon and ensure that everyone understands what they are saying.

Globalisation

The ever-changing and increasingly interconnected world economy presents both opportunities and challenges for operations managers. Globalisation has led to a more complex and uncertain operating environment and increased competition. As a result, operations managers must be able to adapt their strategies and practices to stay ahead of the curve.

Some of the key challenges of globalisation for operations managers include:

- Managing supply chains across borders

- Dealing with cultural differences

- Managing labour in a global market

- Keeping up with technological changes

- Ensuring quality control in a global market

- Managing risk in an uncertain world economy

- Ensuring global compliance with regulations

- Staying ahead of competitors in a global market

- Integrating global operations with local operations and markets

- Minimising cost while maximising efficiency

By understanding the challenges posed by globalisation, operations managers can develop strategies that will help them remain successful in today’s competitive business environment.

More Information:

Operations Management in Hospitals – Know Crucial Functions

What is Operations and Supply Chain Management (OSCM)?