Supply chain modeling is a process used to evaluate and optimize the flow of goods, information and money in a supply chain. It can be used to find bottlenecks, optimize transportation routes and identify opportunities for cost savings. There are different types of supply chain models, each with its advantages and disadvantages. The most popular models are the bullwhip effect, the Beer Game and the newsvendor model. This blog post will explore each of these models and explore some of the best practices for supply chain modelling.

What Is Supply Chain Modeling?

Supply chain modeling is designing and analyzing a supply chain to identify potential improvements. A supply chain model can be used to simulate different scenarios to determine the most efficient or practical course of action.

There are many supply chain models, including static, dynamic, and Monte Carlo simulation models. The most appropriate model for a particular situation depends on the certain goals and constraints of the business.

Some of the benefits of supply chain modelling include:

- Reduced costs

- Increased efficiency

- Improved customer satisfaction

To learn more about supply chain modeling, check out our course Advanced Certificate in Operations, Supply Chain and Project Management to learn more about supply chain management.

What Are The 8 Major Components of Supply Chain Modeling?

- Inventory: This is the most critical component of supply chain modeling as it directly affects the bottom line.

- Transportation: This includes all modes of transportation such as road, rail, air and water.

- Warehousing: This is important for finished goods as well as raw materials. It includes storage, retrieval and packaging.

- Manufacturing: This converts raw materials into finished products. It includes processes like assembly, testing and quality control.

- Procurement: This involves sourcing raw materials and components from suppliers. It also includes contract negotiation and management.

- Distribution: This covers the delivery of finished products to customers through wholesalers, retailers or direct sales channels.

- Customer Service: This comprises activities like order taking, invoicing, returns processing and after-sales service.

- Information Technology: IT is critical in all aspects of supply chain management, from planning to execution.

What is The Significance of Supply Chain Modeling?

In any business, supply chain management aims to minimize costs while maximizing customer service. To accomplish this, managers must plan and control the flow of materials, information and money across the entire supply chain—from suppliers to manufacturers to wholesalers to retailers to customers.

Supply chain modeling is a tool to help managers make better decisions about how to run their supply chains. By creating a model of the supply chain, managers can experiment with different scenarios and see what effect they would have on costs and customer service.

There are many different types of models for supply chain modeling. The most popular type is the linear programming model, a mathematical model that helps managers find the best way to distribute resources to achieve specific objectives. Other types of models include simulation models, queuing models and statistical models.

The best way to choose a model is first to identify the specific problem you are trying to solve. Once you know what you want to optimize, you can select the type of model that will best help you find a solution.

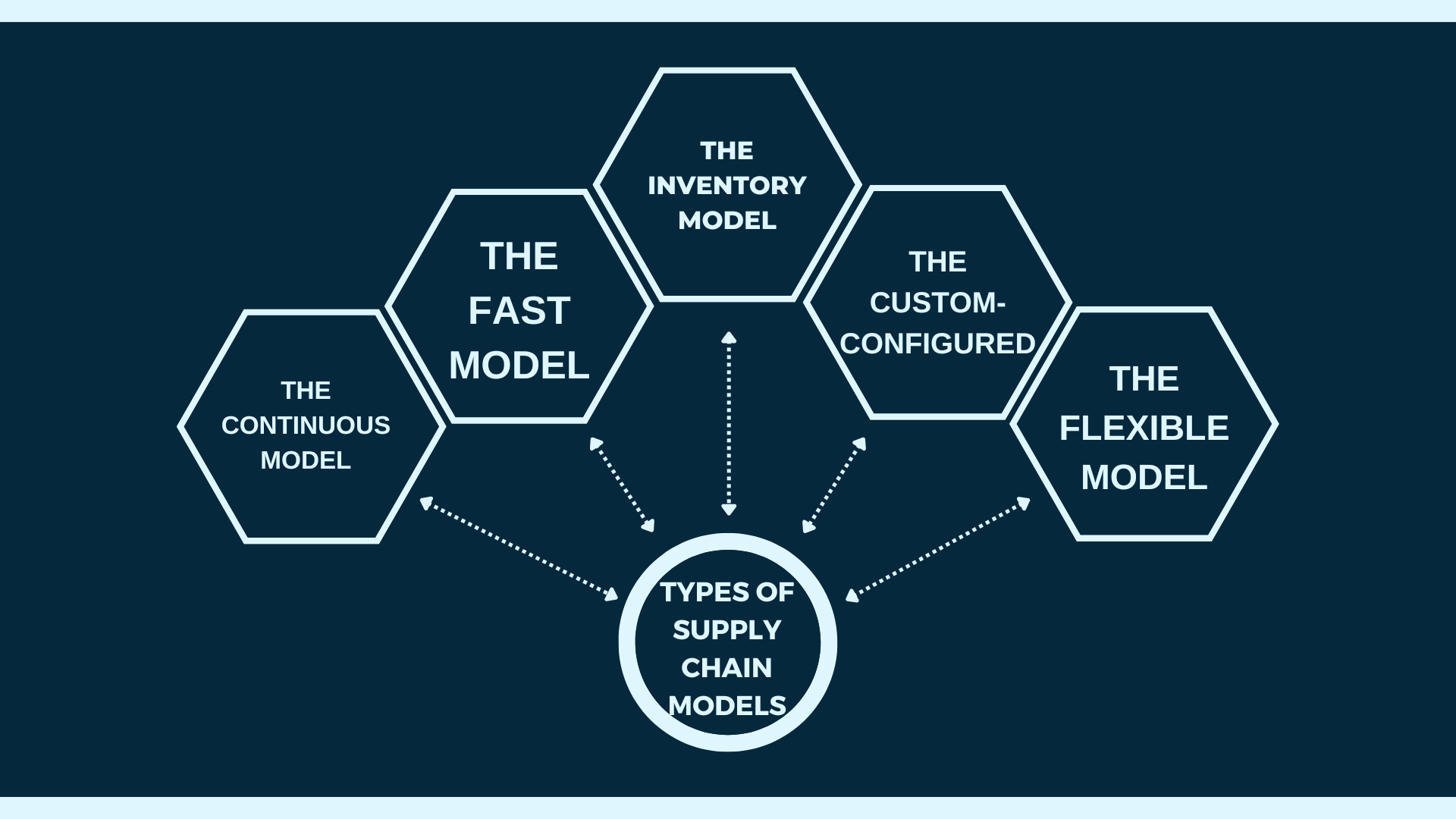

Types of Supply Chain Models

The Continuous Model

A supply chain is defined as a system of facilities and distribution options that receives goods from suppliers and delivers products to customers. The main objective of supply chain management (SCM) is to minimize the total cost of ownership while maximizing the customer service level.

The continuous model is a type of supply chain in which materials flow continuously and constantly through the production process. This type of supply chain is often used in manufacturing industries with a high demand for products and a need for consistent output.

One advantage of the continuous model is that it allows for just-in-time production, which can save on inventory costs. This type of production also eliminates waste, as materials are only produced when needed. A disadvantage of this model is that it can be challenging to change or adapt the production process if there is a sudden change in demand.

If you are considering using the continuous model for your business, it is essential to weigh the advantages and disadvantages to see if this type of supply chain is right for you.

The Fast Model

The Fast Model is a supply chain model designed to help businesses make decisions quickly. This model is based on the principle that the faster a business can make decisions, the better off it will be. The Fast Model is designed to help companies to make decisions about inventory, production, and other aspects of their operations.

Also Read: What Is The Scope Of Operations Management?

The Inventory Model

In business, the term “supply chain” is about transforming raw materials into finished goods and then getting those finished goods into the hands of the customer. The supply chain encompasses everything from the sourcing of raw materials to the manufacturing of products to the distribution and delivery of those products.

There are various inventory supply chain models that businesses can use, depending on their specific needs and goals. The three most common types of supply chain models are make-to-stock (MTS), make-to-order (MTO), and assemble-to-order (ATO).

The make-to-stock (MTS) model is the most common type of supply chain. In this model, finished goods are manufactured and stocked in anticipation of customer demand. When a customer orders, the finished product is simply pulled off the shelf and shipped out. This type of model is often used for fast-moving consumer goods (FMCG) like food and beverages, where customer demand is relatively easy to predict.

The make-to-order (MTO) model is similar to MTS, but businesses only stock raw materials or components instead of finished stocking goods. When a customer places an order, the necessary components are pulled from inventory and assembled into a finished product before being shipped out. This type of model is often used for customized products or products with a long lead time, like furniture or big-ticket items.

The Custom-Configured

A custom-configured supply chain model is designed specifically for a company’s individual needs. This type of model takes into account the specific products, services, and materials that a company uses, as well as the unique way in which its supply chain operates. Custom-configured models are often used by companies with very complex or unique supply chains, such as the automotive or aerospace industries.

There are several benefits to using a custom-configured supply chain model:

- It ensures that a company’s supply chain is optimized specifically for its products and processes.

- It allows a company to take into account changes in its business environment, such as new legislation or market conditions.

- Custom-configured models can be adapted over time to reflect changes in a company’s business model or operations.

The downside of custom-configured models is that they can be very expensive and time-consuming to develop. In addition, they require close collaboration between the modeling team and the company’s decision-makers to succeed.

The Flexible Model

The Flexible Model is a type of supply chain model designed to adapt to changing conditions. This model focuses on flexibility in all aspects of the supply chain, from manufacturing to distribution. The Flexible Model aims to provide a greater level of customer service while still being able to respond quickly to changes in demand.

Many businesses use the Flexible Model as their primary supply chain model. The Flexible Model allows businesses to keep inventory levels low, which can reduce costs and increase profits. This model is especially popular in industries where demand can change rapidly, such as the fashion industry.

The biggest advantage of the Flexible Model is its ability to adapt to changing conditions. This flexibility can help businesses avoid stockouts and disruptions in the supply chain. The Flexible Model can also help companies to save money by reducing the need for safety stock.

There are some challenges associated with using the Flexible Model as your primary supply chain model:

- This model requires close coordination between all supply chain members. This can be difficult to achieve, especially if your suppliers are worldwide.

- This model can be expensive to implement since it requires more resources and infrastructure than other models.

- The Flexible Model may not be suitable for all types of products or businesses; for example, it may not work well for products with long lead times or high levels of customization.

What Are The Best Practices For Supply Chain Modeling?

The best practices for supply chain modeling vary depending on the specific model being used. However, some general best practices apply to all models.

When creating a supply chain model, it is essential first to understand the specific needs of the business and what they hope to achieve with the model. Once this is understood, the next step is to choose the appropriate modelling approach and technique.

After the model has been created, it is important to validate it against accurate data. This will help ensure that the model accurately represents the reality of the business’s supply chain.

Finally, once the model has been validated, it should be used to test different scenarios and “what if” situations. This will help businesses make better decisions about their supply chain in the future.

What Are The Challenges of Supply Chain Modeling?

The main challenge associated with supply chain modeling is the complexity of the relationships between the various supply chain elements. For example, a change in one element (such as production) can have a ripple effect in the supply chain, affecting other aspects, such as transportation and inventory.

Another challenge is that the data used to build models is often imperfect or incomplete. This can make it challenging to accurately capture all relevant relationships between different supply chain elements. Additionally, real-world data can be noisy and may contain outliers that can throw off results.

Finally, another challenge is that multiple objectives often need to be optimized when designing a supply chain (e.g., minimizing cost while maximizing customer satisfaction). Finding an optimal solution that meets all objectives can make it challenging.

Also Read: How to formulate Advanced Supply Chain Strategy?

How To Become A Supply Chain Manager?

There is no one-size-fits-all answer; the best way to become a supply chain manager may vary depending on your prior experience and education. However, there are some basic steps that you can take to increase your chances of becoming a successful supply chain manager.

- Firstly, it is essential to gain experience in the field of supply chain management. This can be done through working in a relevant position within a company or by completing an internship or traineeship program.

- Secondly, earning a degree in SCM or a related field, such as business management or logistics, is helpful. While not required, having an advanced degree may give you an edge over other candidates when applying for jobs.

- Thirdly, consider obtaining professional certification through reputed organizations. This will give you an upper edge in the competition. These credentials can demonstrate your commitment to professional development and provide employers with evidence of your knowledge and skill set.

- Finally, networking is another critical component of becoming a successful supply chain manager. Attend industry events and connect with other professionals through online forums and social media platforms like LinkedIn to make valuable contacts who can help you further your knowledge.

Conclusion

Modeling your supply chain is a critical part of running a successful business. The type of model you use will depend on the specific needs of your business, but there are some best practices that all companies should follow. By understanding the different types of models and how to implement them best, you can ensure that your supply chain is as efficient and effective as possible.

Supply chain management is indeed a flourishing field, and starting a career in the field would be the best decision. Whether you want to fine-tune your skills as a professional or start as a fresher in the industry, we have a course that will just into your requirements. Check out our Advanced Certificate in Operations, Supply Chain now to know more!

More Information:

What is Green Supply Chain? An Overview

Green Supply Chain Management: What It Is and Why It Matters?