PMP Certification Training

- 86k Enrolled Learners

- Weekend/Weekday

- Live Class

A quality assurance plan is more of a detailed document that outlines how a company will ensure the quality of its products or services. It includes all quality control procedures, policies, and standards that a company must follow to ensure that its products or services meet all customer requirements. Creating a quality assurance plan may seem daunting, but it doesn’t have to be. Following these 9 steps, you can create a great quality assurance plan to help your company meet all its quality goals.

The first step in creating an efficient quality assurance plan is to define your objectives and goals. It will help you ascertain what to do to ensure that your products or services meet the required standards.

There are some significant things to review when defining objectives and goals:

Once you have reviewed these factors, you can start setting objectives and goals. Make sure they are (SMART):

Setting procedures and policies for all is the first step in creating a quality assurance plan. By doing this, you will ensure that everyone involved in the project understands what is expected of them and how they should go about meeting those expectations.

There are various things to consider when setting procedures and policies, including:

Once you have established procedures and policies for all aspects of the project, you can create specific quality assurance plans for individual tasks.

When creating a quality assurance plan, scheduling roles and responsibilities is essential. It will ensure that everyone knows their part in the process and that tasks are properly completed. Here are some tips for scheduling roles and responsibilities:

By scheduling roles and responsibilities, you can create a quality assurance plan that will run smoothly and efficiently.

Documentation is an integral part of quality assurance. It provides a record of what has been done and can be used to help track progress and identify areas for improvement. Documentation can be divided into different phases, each with its purpose.

The first phase of documentation is the planning phase. It is when the project manager creates a high-level plan for the project. The plan includes the overall objectives, scope, timeline, and budget. This phase also includes creating a quality assurance plan. The quality assurance plan outlines how the project will be monitored and controlled.

The second phase of documentation is the execution phase. This is when the actual work of the project is carried out. During this phase, documents are created that describe how the work was done and what was accomplished. These documents can help assess whether the project met its objectives and identify any areas for improvement.

The third phase of documentation is the monitoring and evaluation phase. It is when quality assurance activities are carried out to ensure that the project remains on track and meets its objectives. If problems are identified, they are documented, and corrective actions are taken to address them.

The fourth and final phase of documentation is the closure phase. This is when the project is completed, and all remaining work is documented. The closure report includes a summary of the project, an assessment of its success, and recommendations for future projects.

Also Read: How To Become A Better Project Manager? Top 10 Tips

Reviewing and auditing in a quality assurance plan is a process of monitoring the quality of the products or services being delivered by a company. This can be done internally by employees or externally by independent third-party organizations. The purpose of reviewing and auditing is to ensure that the company meets its quality standards and delivers its products or services consistently and reliably.

There are many benefits to conducting reviews and audits as part of a quality assurance plan:

Testing helps ensure that products and systems are designed and built correctly and meet customer expectations. The testing phase in the quality assurance plan is verifying that a product or system meets the requirements specified in the design.

It also includes checking to see if the product or system works as expected and identifying any areas where it does not meet the requirements.

This allows businesses to make necessary improvements before release, which can save time and money in the long run. A well-executed testing phase can also help to boost customer confidence in a product or service.

Functional testing focuses on the specific features of your software and how well they work. For example, if you’re developing a web application, functional testing would involve:

Non-functional testing assesses how well your software performs in terms of things like speed, scalability, and security. This type of testing is significant for web applications since they need to handle large amounts of traffic and data.

There is no one-size-fits-all answer, as the troubleshooting process will vary depending on the specific quality assurance plan that you have in place. However, there are some general steps that you can take to troubleshoot any problems that may arise:

Project control in a quality assurance plan is the process of monitoring and regulating the progress of a project to ensure that it meets the requirements for quality. It involves setting up a system to track progress, identify issues and risks, and take corrective action as needed.

Project control helps to ensure that a project stays on track and meets its objectives. It can help identify potential problems early on, so they can be catered to before they cause significant delays or cost overruns. It also allows stakeholders to see the project’s progress and whether it is meeting their expectations.

When it comes to creating a quality assurance plan, training is one of the most critical steps. After all, if your team isn’t adequately trained on how to implement and follow the plan, it won’t be effective.

Two main types of training should be included in your quality assurance plan:

Risk management is a vital element of any quality assurance plan. By identifying and assessing risks early on, you can avoid potential problems down the road. Check out a few tips for creating an effective risk management plan:

By following these steps, you can create an effective risk management plan to help keep your business on track to success.

When creating a quality assurance plan for your project, there are many aspects to consider. Keep these key points in mind:

1) Define your objectives and success criteria upfront. It will help you determine what needs to be included in your plan and how to measure success.

2) Create a detailed plan of action. Include who is responsible for each task, when it needs to be completed, and what the deliverables will be.

3) Ensure you have adequate resources to carry out the plan. This includes people, time, and budget.

4) Implement the plan and track progress. Regularly review results against your objectives and make adjustments as needed.

5) Be prepared to adapt. Things will inevitably change during your project, so be flexible and adjust your plans accordingly.

Also Read: Steps To Create A Successful Go-To-Market Strategy

The best practices of a quality assurance plan are necessary to follow to create a great plan. Four main best practices should be followed:

By following these best practices, you can be sure that your quality assurance plan will be effective and help you to achieve your desired results.

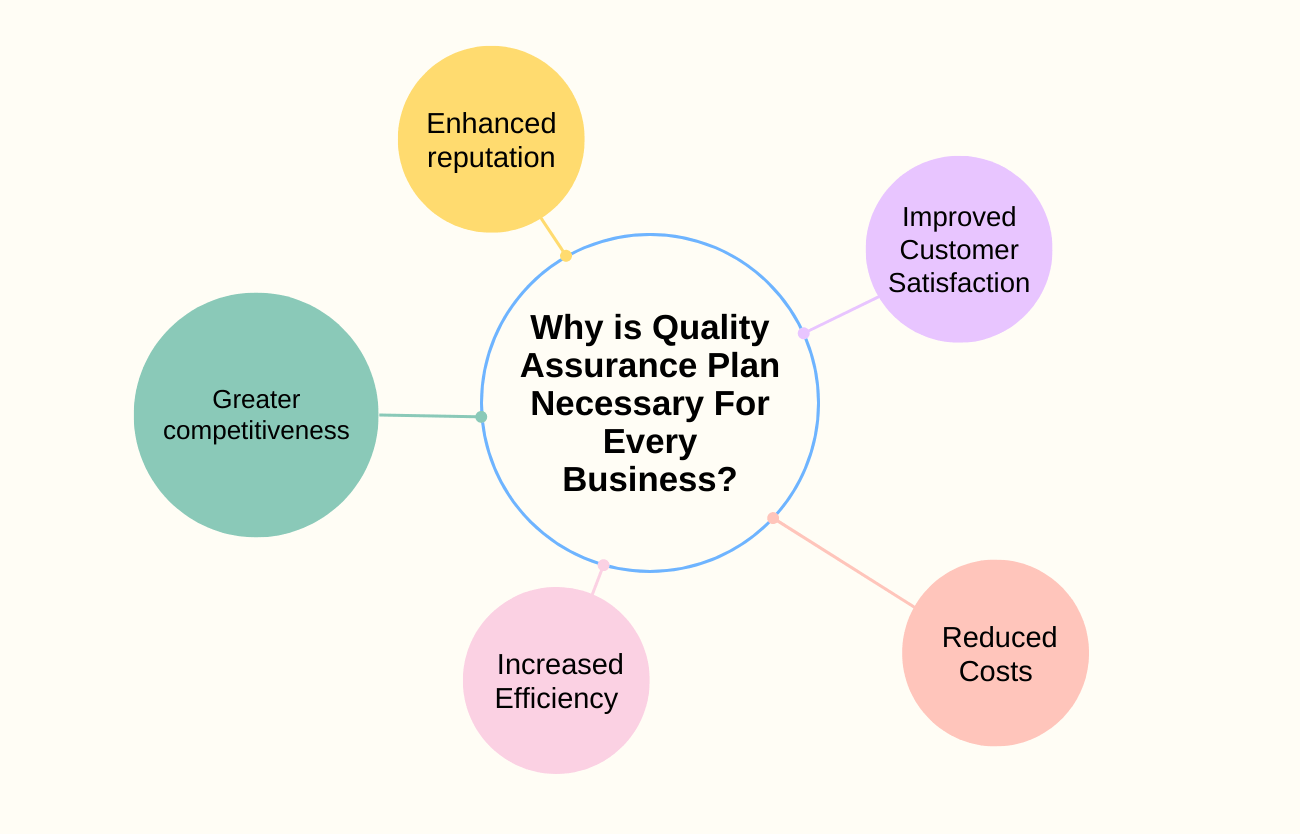

It is a document that outlines the processes and procedures that will be followed to ensure quality standards are met. It is an essential tool for any business, as it can help to improve customer satisfaction, reduce costs, and increase efficiency.

There are many benefits to having a quality assurance plan in place; below, we will explore five of them in more detail.

One of the essential advantages of having a quality assurance plan is that it can lead to improved customer satisfaction. Customers who receive products or services that meet their expectations are more likely to be satisfied with the purchase. This can lead to more business and positive word-of-mouth marketing for your company.

Another benefit of implementing a quality assurance plan is that it can help to reduce costs associated with rework or product defects. By ensuring that products meet quality standards before they are released to customers, businesses can avoid the costly process of fixing issues after the fact. In some cases, this can also lead to reduced warranty claims.

Having a quality assurance plan can also help increase efficiency within your business operations. When everyone understands the procedures that need to be followed and there is a straightforward process for measuring quality, it becomes easier to streamline operations and eliminate wastefulness. This increased efficiency can save your company time and money in the long run.

In today’s marketplace, businesses need to be able to compete on quality as well as price. Having a quality assurance plan in place can demonstrate to potential customers that you are serious about providing high-quality products and services. It can provide you with a competitive edge and help you to win new business.

Finally, another benefit of having a quality assurance plan is that it can help to enhance your company’s reputation. When customers know that you have high standards for quality, they will be more likely to trust your brand. This increased trust can lead to more business and further opportunities down the line.

Quality assurance is a process that helps to ensure that products and services meet the requirements of customers or clients. By creating a quality assurance plan, businesses can develop specific goals and objectives to meet quality standards. By following these steps, you can be sure that your quality assurance plan will be comprehensive and effective in helping your business meet its quality goals.

To successfully manage operations, supply chains, and projects, it’s essential to understand how the quality assurance and control processes work. Our Advanced Certificate in Operations, Supply Chain and Project Management course can help you gain that knowledge.

This comprehensive course delves into operations management, inventory planning, supply chain optimization, project management principles, and quality assurance and control. It also includes exercises to help you apply the concepts in real-world scenarios.

A Beginner’s Guide To Operations Management

Major Decision Areas In Supply Chain Management

How To Achieve Optimum Professional Growth

Brand Management v/s Product Management: Know Key Differences

Thank you for registering Join Edureka Meetup community for 100+ Free Webinars each month JOIN MEETUP GROUP

Thank you for registering Join Edureka Meetup community for 100+ Free Webinars each month JOIN MEETUP GROUPedureka.co