What is operations management? It is a question that many people ask, and it can be challenging to provide a concise answer. Simply put, operations management (OM) definition can be the process of planning, organising, leading, and controlling the resources and activities of a company to achieve its goals. It encompasses everything from production and manufacturing to logistics and customer service. In this blog post, we will explore operations management definition in more detail and provide operations management examples of how it is used in business.

Definition Of Operations Management

The definition of operations management (OM) is the process of overseeing, coordinating, and designing business operations to improve efficiency and effectiveness. It is what drives the entire production process, from start to finish. The responsibilities of an operations manager include planning, organising, directing, and controlling the resources needed to produce a company’s products or services.

Operations management is a vital function in any business or organisation. It can make the difference between a company that can efficiently produce high-quality products or services and one that is not. Operations managers must clearly understand what their role entails and what it takes to manage operations effectively.

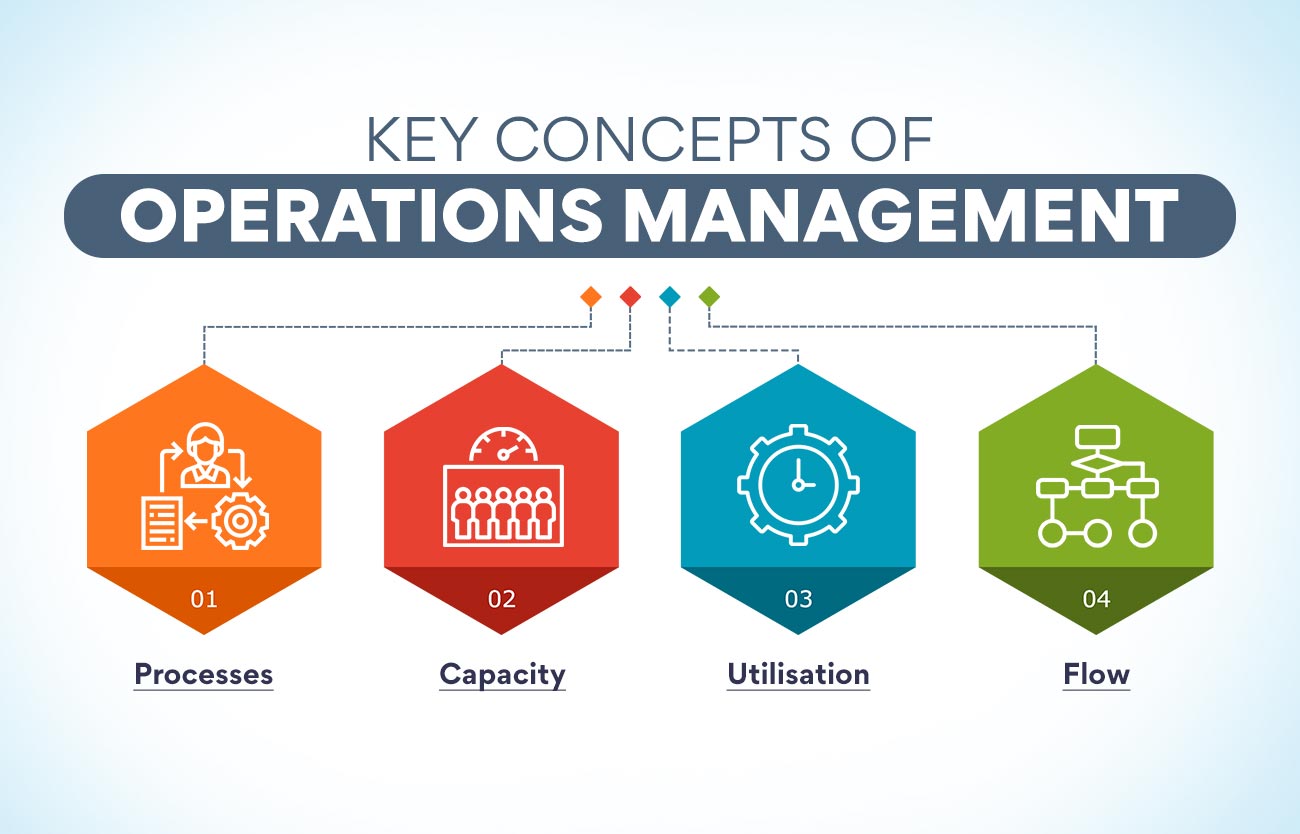

A few key concepts are important to understand when it comes to operations management. These include:

Processes: All businesses have processes that need to be managed to produce their products or services. Operations managers are responsible for ensuring all the processes are efficient and effective.

Capacity: The amount of work a company can do in a given period is known as capacity. Operations managers must be aware of a company’s capacity to ensure that it is being used effectively.

Utilisation: This measures how much of a company’s capacity is being used. Operations managers strive to ensure that utilisation is high to maximise efficiency.

Flow: The movement of resources through a company’s production process is known as flow. Operations managers need to ensure that resources flow smoothly to avoid bottlenecks.

While these are only a few concepts essential to understanding when it comes to operations management, many others make a difference. By comprehending these concepts, you can become an effective operations manager.

If you are interested in operations management, there are several resources that you can turn to. For instance, we have an insightful course on operations management to get started on the journey to becoming an operations manager.

Different Types of Operations

Manufacturing: It is the process of designing, creating, and delivering goods. The manufacturing process requires raw materials, labour, and equipment. Operations management in manufacturing is responsible for planning, scheduling, and controlling these elements. It is essential to have an efficient manufacturing process to produce quality products on time.

Service: It is an activity that provides a service to customers. Service operations require human labour and resources to provide the service. Operations management in service is responsible for managing the service delivery process to customers. A smooth and seamless service function will generate more revenue and expand the business.

Also Read: What Are The Objectives Of Operations Management?

Retail: Operations management in the retail industry ensures that stores run smoothly and efficiently. It includes tasks such as stocking shelves, managing inventory, and providing customer service. Retail operations managers must be able to plan and execute tasks effectively to be successful. Operations managers in the retail industry typically have a background in business or management and overlook the daily operations of store locations.

Hospitality: It is the process of managing the day-to-day operations of a business. The goal of operations management is to streamline the company’s operations to make them as efficient and effective as possible. Operations managers look after all aspects of the business to run smoothly and ensure that the company’s goals are met. For instance, the operations manager in a hotel would be responsible for managing the front desk, housekeeping, and catering staff.

Logistics: Logistics entails planning, implementing, and controlling the flow of products and services from the point of origin to the point of consumption. In layman’s terms, logistics is the management of the flow of resources between two points. Logistics is critical to operations management because it determines how efficiently a company can produce and deliver its products or services.

Supply Chain: The process that takes place from acquiring raw materials to delivering the finished product to the customer is called a supply chain. It is the set of activities that transforms inputs into outputs. In operations management, the main goal is to manage the transformation process to run smoothly and efficiently. Operations management in supply chain management includes managing resources, information, and finances.

There are many things that you need to learn regarding operations management. Want to start your career on a great note? Check out our Advanced Program in Operations, Supply Chain, and Project Management to give your career a thrust.

How Does Operations Management Works?

The definition of Operations management entails overseeing, designing, and controlling the production of goods or services. It involves managing the resources that are necessary for the creation of a product or service. Operations management ensures that the production process is efficient and effective. The goal of operations management is to create value for the organisation.

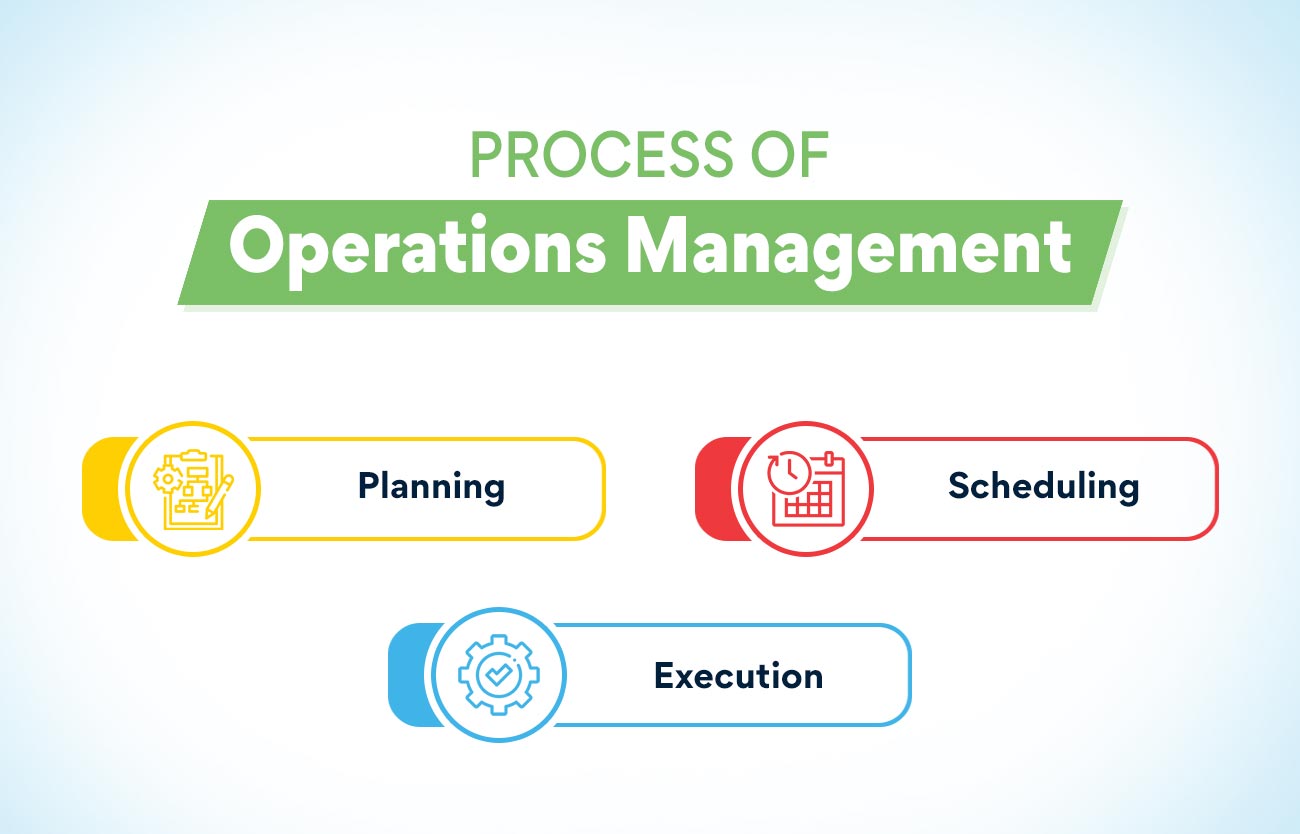

Process of Operations Management:

Operations management is a process that consists of three main functions:

- Planning: This is the process of determining what needs to be done and when it needs to be done. With OM, you create a plan that will guide the operations of your business.

- Scheduling: It decides when each task will be completed. In operations management, you create a schedule to ensure all tasks are completed on time.

- Execution: It is about carrying out the plan. In operations management, you execute the plan by ensuring that all resources are used efficiently and effectively.

What Are The Examples of Operations Management?

Operations management ensures all business operations are working efficiently by optimally utilising all the resources to meet customer requirements. It is concerned with managing the processes that create and deliver the company’s primary products and services.

Common operations management activities that dominate the process include:

- Product and service design

- Process selection

- Capacity planning

- Quality control

- Inventory management

- Scheduling

- Supply chain management

- Project management.

Operations Management Examples

A company’s manufacturing process: A manufacturing company will need to design its processes and set up quality control procedures to determine all the products meet customer requirements most efficiently. The company will also need to determine the most efficient way to use its resources and schedule production to meet customer demand.

A company’s sales and marketing processes: It is essential to manage a company’s sales and marketing processes because they are what generate revenue. If these processes are not managed effectively, a company will not be able to generate the revenue it needs to sustain itself.

The operations of a call centre: In a call centre, operations management is responsible for activities such as planning staffing levels, monitoring performance, and scheduling breaks. It is also accountable for making sure that the call centre has the necessary equipment and supplies. Operations management in a call centre will also typically be responsible for training new employees.

The creation of a new product: While creating a new product, several important considerations go into the operations management process. Market research, target audience, product design, and production planning all ensure that the product is successful.

Also Read: Operations Management in Hospitals – Know Crucial Functions

Creating and maintaining inventory: To keep up with customer demand, businesses need to maintain a certain level of inventory. This involves forecasting customer demand and ensuring that there is enough inventory on hand to meet this demand.

Strategies of Operations Management

There are different strategies of operations management that companies use to make their business processes more efficient.

Reducing Costs: One way to make operations more efficient is to reduce costs. It can be done by improving productivity and eliminating waste. Omnicom, for instance, is a company that has been able to save millions of dollars by reducing costs in its operations. It will be able to reinvest these savings into other areas of the business or use them to improve its bottom line.

Improving Quality: Operations management is also responsible for improving the quality of products and services. It can be done through quality control, which sets standards and then measures whether the products or services meet those standards. If they don’t, operations managers work to identify the causes of the problems and find solutions. Quality improvement is a never-ending goal for operations managers because there’s always room for improvement, no matter how good the quality already is.

Improving Productivity

Operations managers are also responsible for improving productivity. By improving productivity, operations managers can help improve their company’s bottom line. For instance, if an operations manager can find a way to reduce the amount of time it takes to complete a task, they can save the company money. In addition, if an operations manager can improve the quality of their product, they can increase sales and revenue. There are several ways, such as process improvement, quality control, and employee training.

Optimally Utilising Data

Data is the lifeblood of any operations manager worth their salt. To make accurate decisions regarding the production process, one must have access to accurate and up-to-date data. The data can be derived from various sources, such as sales reports, customer surveys, or even data gathered from the production process itself. Once all the data is collected, it must be analysed to identify any trends or patterns. This analysis can be used to decide how to improve the production process or predict future demand.

Setting Goals And Forecasting

Operations management is all about setting goals and forecasting. It includes figuring out what needs to be done to achieve desired results, as well as predicting future trends. To ensure that your organisation is running smoothly, operations management must be deployed. Only through this understanding will you be able to set appropriate goals and make accurate forecasts.

Enhance Collaboration

Definition of Operations management is a domain of business concerned with producing goods and services and involves ensuring that business operations are efficiently managed with as minimal resources as possible. For this, it is imperative to have effective collaboration among various business departments. All team members must be aware of their roles and responsibilities to achieve this. They need to be able to work together harmoniously to avoid any conflict

Human Resource Management

HR management is a process that helps organisations manage and control their employee-related activities. It includes attracting and hiring employees to train and development, performance management, and employee relations. Operations management can be made more efficient by HR management practices such as workforce planning and succession planning.

Improve Supply Chain

The supply chain involves all the processes that transform raw materials into finished products and deliver them to the end customer. Operations management improves the efficiency and effectiveness of an organisation’s supply chain. In other words, it ensures that goods and services are produced and delivered promptly and cost-effectively.

The Bottom Line

Without operations management, businesses would be unable to produce goods or services. This critical management area ensures that all production aspects run smoothly and efficiently. It is most vital during periods of high demand when businesses must meet customer expectations while maintaining quality standards.

Operations management is responsible for planning, coordinating, and controlling all the resources and activities necessary to produce a company’s goods and services. From raw materials to finished products, operations management oversees every step of production. In today’s fast-paced business world, efficient operations management is essential to success.

If you are eager to study more about operations management, check out our comprehensive certificate course. It covers everything from operations management definitions and examples to the different types of operations management. So what are you waiting for? Accelerate your career with our insightful and engaging course on operations management.

More Information:

Understanding Talent Management And Its Importance

Strategic Workforce Planning: Steps and Process